TC-WEIGHT SERIES OVERHEAD CRANE REMOTE CONTROL

The TC-WEIGHT Series Industrial Remote Control Is The Most Specialized Product Of The RICHWAVE Series For Guiding And Controlling Weight In All Types Of Cranes.

TC-WEIGHT SERIES OVERHEAD CRANE REMOTE CONTROL

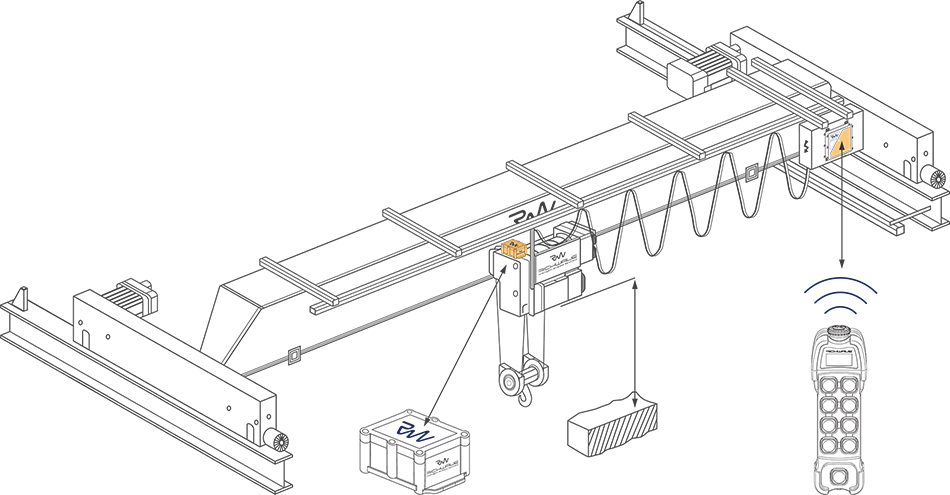

RICHWAVE TC-WEIGHT Series Overhead Crane Remote Control (Abbreviated As TW), With Its Advanced Design And (Dedicated Load Cell Module), Allows Users To Accurately Monitor Weight And Control Equipment Simultaneously. This Series, Especially In Display Models, Is Designed For Various Industries Such As Mining, Petrochemical, Transportation, Iron And Steel Metallurgy, And With Its Special Features, Has Been Able To Gain A Special Place In Industrial Environments.

The Load Cell Module Communicates With Other Parts Of The Remote Wirelessly, Which Not Only Makes Installation And Setup Easy, But Also Reduces The Need For Complex Wiring And Provides Greater Flexibility For Use In Different Environments.

Combining Modern Technologies And Precise Performance, The TC-WEIGHT Series Remote Control Allows Users To Manage Their Industrial Operations More Easily. This Device Not Only Increases The Productivity And Safety Of Human Resources, But Also Helps To Save Significant Time And Money By Reducing Production Stops And Costs Due To Breakdowns Or Repairs.

If You Are Looking For A Reliable Solution For Smart And Efficient Control Of Your Equipment, The TC-WEIGHT Series Remote Control Is An Unbeatable Choice.

LOAD WEIGHT CONTROL MANAGEMENT TECHNOLOGY

Weight Control Technology In Industrial Remote Controls Is One Of The Advanced Capabilities In The Field Of Lifting, Which Plays An Important Role In Increasing Safety, Accuracy And Optimizing The Performance Of Lifting Equipment. This System, Using Precise Force Sensors (Load Cells) And Real-Time Data Processing, Allows Continuous Measurement Of The Weight Of The Load And Its Display On The Remote Control Display. This Capability Allows The Operator To Observe The Permissible Load Limits And Prevent Overloading And Unnecessary Tensions On The Crane Structure And Lifting Cables. Visual Models Are Equipped To Notify The Operator When The Load Is Approaching The Final Capacity Of The Structure And, If Necessary, Apply Control Limits On The Crane Movement.

The Use Of This Technology Reduces Wear And Tear On Mechanical And Electronic Equipment, Thereby Extending The Useful Life Of Key Components Such As Engines, Gearboxes, Brakes And Wiring Harnesses. In Addition, Data Recorded From The Transported Loads Can Be Sent To Industrial Monitoring Systems And Used To Analyze Performance, Monitor Unloading Trends And Predict Maintenance Needs. Integration With Industrial Management Platforms Enables Intelligent Monitoring And Control Of Unloading Operations, Which In Addition To Increasing Safety Levels, Improves Overall Production Line Efficiency And Reduces Unforeseen Maintenance And Repair Costs.

TC-WEIGHT series applications

The Main Application Of The TC-WEIGHT Series Is In The Automotive, Road And Construction, Rail Transportation, And Overhead Crane Industries, Where Simple, Yet Stable And Safe Operation Is Desired.

TC-WEIGHT SERIES FEATURES

The TC-WEIGHT Series, With Its Wide Range Of State-Of-The-Art Technologies, Has Improved And Enhanced The Productivity And Performance Of Orders, Saved Costs, And Extended The Life Of Machinery.

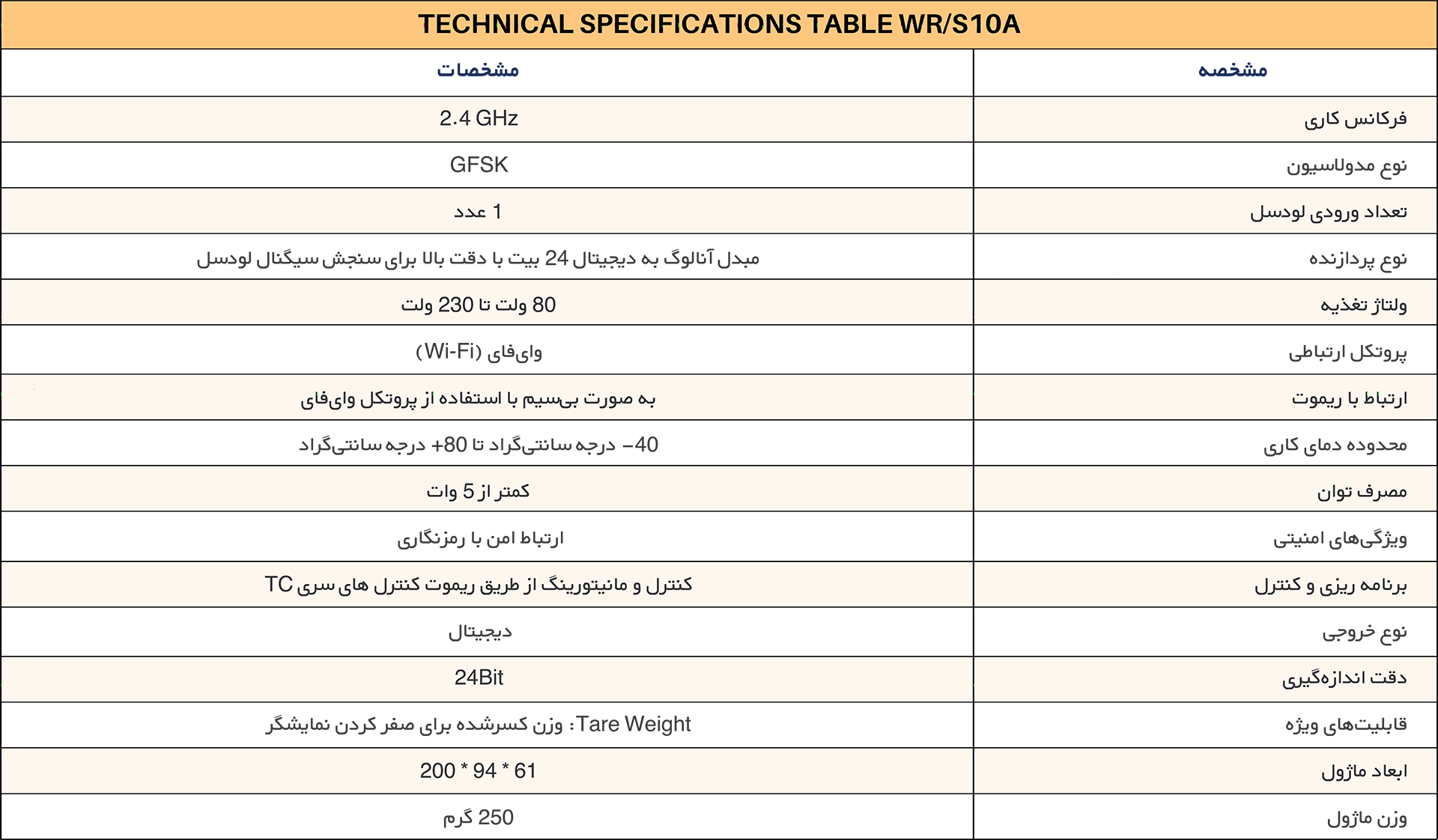

TC-WEIGHT SERIES SPECIFICATION TABLE

The TC-WEIGHT Series Industrial Remote Control Has Unique Features That Distinguish It From Other Current Competitors In The Iranian Market.